With the continuous evolution of modern office methods, the relationship between ergonomic design and work efficiency has received increasing attention. As a key height adjustment component in office chairs, Office Chair Gas Lift Cylinder undertakes the important task of frequent lifting and adjustment in daily use. Especially in high-intensity office scenes, such as call centers, design studios or shift positions, employees may adjust the seat height several times a day to adapt to different working postures or equipment requirements. Therefore, in this high-frequency lifting and adjustment environment, whether the gas pressure rod can continue to provide stable support and safe lifting has become one of the core indicators for measuring the overall quality and safety of office chairs.

1. Basic structure and working principle of gas pressure rod

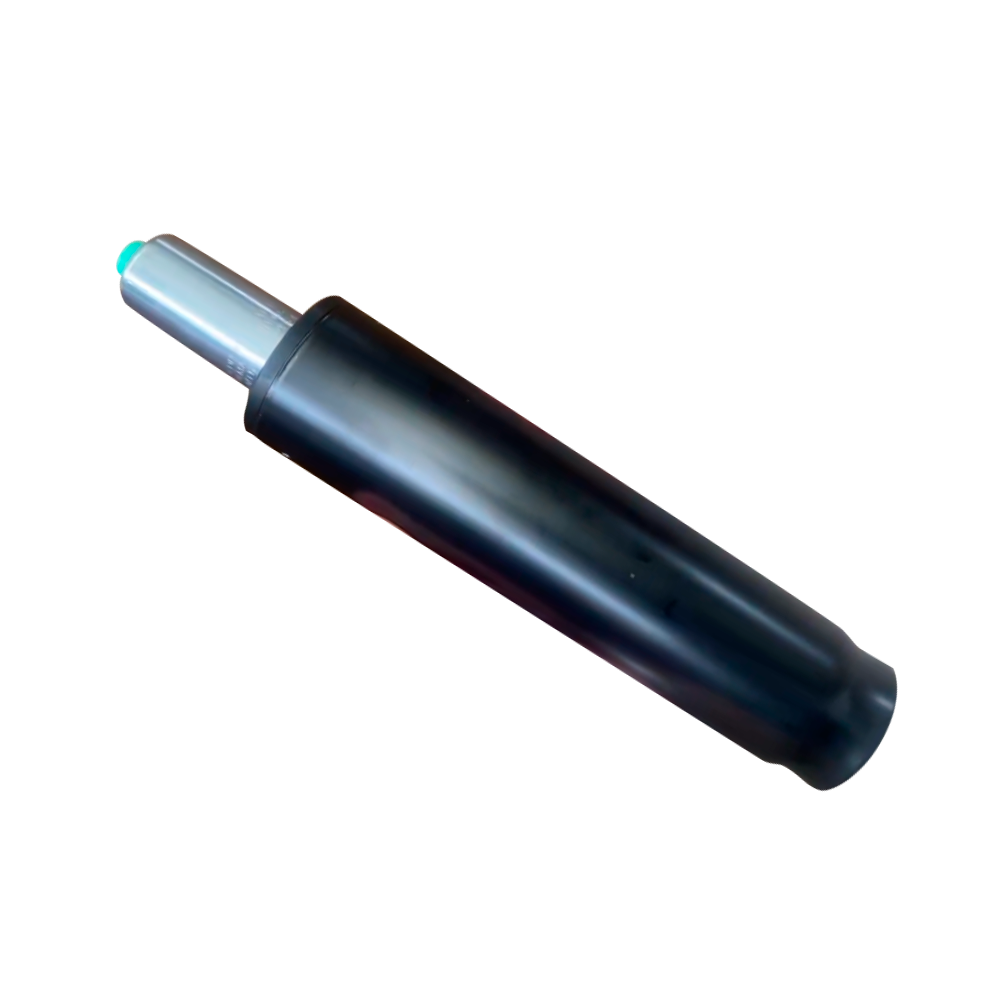

The gas pressure rod of an office chair is essentially a mechanical device that uses compressed gas to achieve lifting and adjustment, usually installed between the chair base and the seat. Its basic structure includes:

Outer Tube: As the main load-bearing shell, it is usually made of high-strength steel;

Piston Rod: The telescopic part, connected to the bottom of the seat, moves up and down through gas pressure;

Sealing system: Prevent gas leakage and maintain internal pressure balance;

Lock/release mechanism: The user controls the lifting state through the pull rod under the seat. Press it to adjust the height freely, and release it to automatically lock the position.

When the user presses the adjustment rod, the internal valve opens, and the gas flow causes the inner rod to slide up and down; after releasing it, the valve closes, and the gas pressure fixes the inner rod at a certain height, thereby achieving a stable support effect.

2. Challenges to the performance of gas rods due to high-frequency use

In actual office environments, especially for positions that require long-term sitting work, gas rods are in a state of frequent lifting and lowering almost every day. This high-frequency, repetitive operation will cause the following pressures on the gas rod:

Increased wear: Frequent lifting and lowering will accelerate the friction between the piston and the sealing ring, resulting in an increased risk of gas leakage.

Fatigue deformation: metal materials may develop microcracks or plastic deformation after bearing human weight and repeated stretching and compression for a long time.

Decreased stability: If the internal structure of the gas pressure rod is damaged, it may cause uneven lifting, jamming or even sudden collapse.

Increased safety risks: If the gas pressure rod does not meet the relevant safety standards, there are safety hazards such as explosion and breakage.

Therefore, in such high-intensity use scenarios, the gas pressure rod not only needs to have good mechanical properties, but also needs to meet strict safety regulations and service life requirements.

3. Key factors to ensure stable support

1. Material selection and processing accuracy

High-quality gas pressure rods usually use cold-drawn seamless steel pipes or stainless steel pipes as outer cylinders, which have higher compressive strength and corrosion resistance. At the same time, the internal piston and seals are made of high-wear-resistant rubber or polytetrafluoroethylene (PTFE) materials, which can effectively reduce friction loss and extend service life.

In addition, precision processing technology is also crucial. For example, the surface of the inner rod is chrome-plated to improve smoothness and rust resistance, and the matching clearance between the inner and outer cylinders must be controlled within a reasonable range to ensure smooth lifting and not easy to get stuck.

2. Gas sealing and pressure control system

The core of the gas pressure rod is the inert gas (usually nitrogen) filled inside it, which realizes the lifting function through the change of air pressure. High-quality gas pressure rods adopt a multi-layer sealing structure, including O-rings, lip seals and dust covers to ensure long-term gas sealing without leakage.

Advanced pressure control systems can also automatically adjust the air pressure output according to the load size, so that users of different weights can get a consistent lifting experience and support effect.

3. Structural optimization and ergonomic design

Modern office chair gas pressure rods often combine ergonomic design concepts, such as:

Multi-stage lifting adjustment: supports more precise height setting to meet the matching needs of different heights and table heights;

Buffering rebound design: avoid impact on the ground or body during rapid descent;

Silent operation: reduce noise interference during lifting and lowering, and improve office comfort.

These designs not only improve user experience, but also help reduce the structural burden of gas pressure rods under frequent operation.

4. Technology and certification standards to ensure safe lifting

In order to cope with the challenges brought by high-frequency use, gas pressure rod manufacturers usually follow internationally accepted quality and safety standards, the most representative of which are:

SGS certification: an independent testing service provided by SGS Switzerland to evaluate the performance of products in terms of durability, load-bearing capacity and safety;

BIFMA test standard: a standard set by the American Office Furniture Association, requiring gas pressure rods to withstand at least 100,000 lifting tests;

EN 1335 standard: a mandatory European standard for office chair safety, which stipulates that gas pressure rods must pass multiple tests such as burst pressure tests and fatigue tests.

Gas pressure rods that pass these certifications usually have a higher safety factor and longer service life, and are especially suitable for enterprise-level office environments.

In addition, some high-end brands have also introduced explosion-proof designs. Even if gas leaks in extreme cases, it will not cause a violent explosion, but slowly release pressure to protect the safety of users to the greatest extent.

5. Correct use and maintenance suggestions

In addition to the product quality itself, the correct use and regular maintenance of the user are also the key to ensure the long-term and stable operation of the gas pressure rod:

Avoid overloading: Each gas pressure rod has a rated load-bearing range, and exceeding the limit will accelerate structural fatigue;

Keep clean and dry: Avoid dust from entering the cylinder and affecting the sealing performance;

Check the lifting function regularly: If there is a jam, abnormal sound or inability to lock, it should be replaced in time;

Choose a formal channel to purchase: Give priority to purchasing office chairs or gas pressure rod accessories with authoritative certification.

In the modern office environment, although the gas pressure rod is only a small component of the office chair, it directly affects the user's sitting comfort, work efficiency and personal safety. In the face of the need for high-frequency lifting and adjustment, high-quality gas pressure rods can maintain excellent support and safety performance during long-term use through selected materials, precision manufacturing, scientific design and strict certification.

Whether it is a company purchasing an office chair or an individual purchasing office furniture, attention should be paid to the quality and certification standards of the gas pressure rod to ensure office health and safety from the source. Only in this way can we truly achieve the goal of building a "people-oriented" office environment.

English

English русский

русский